-

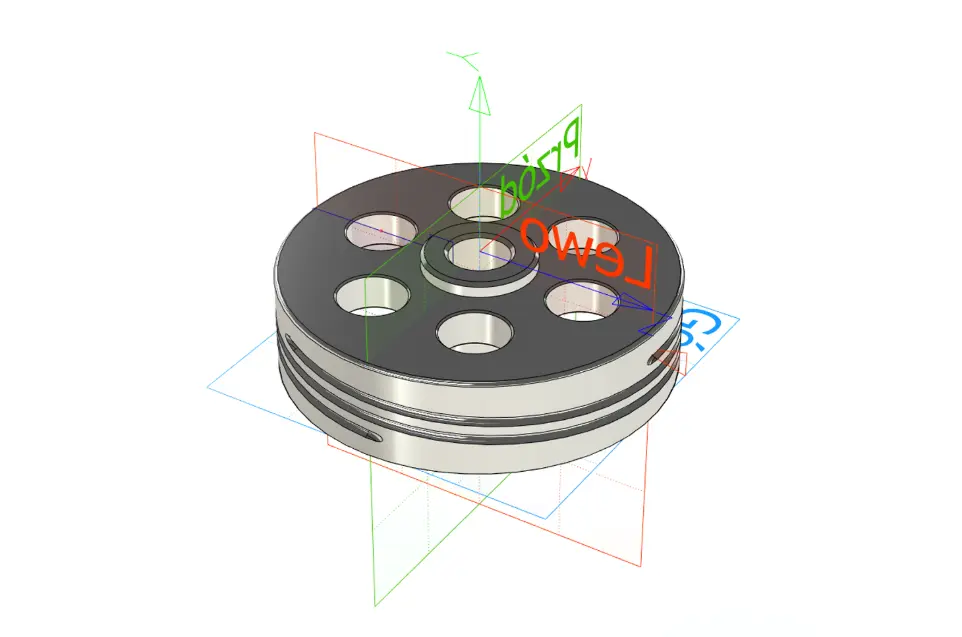

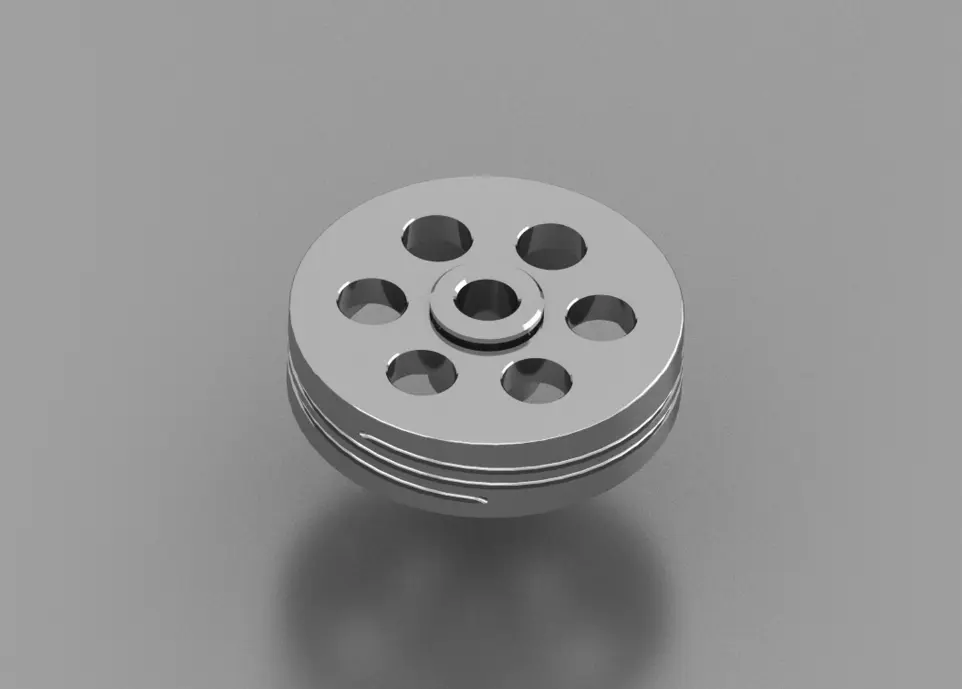

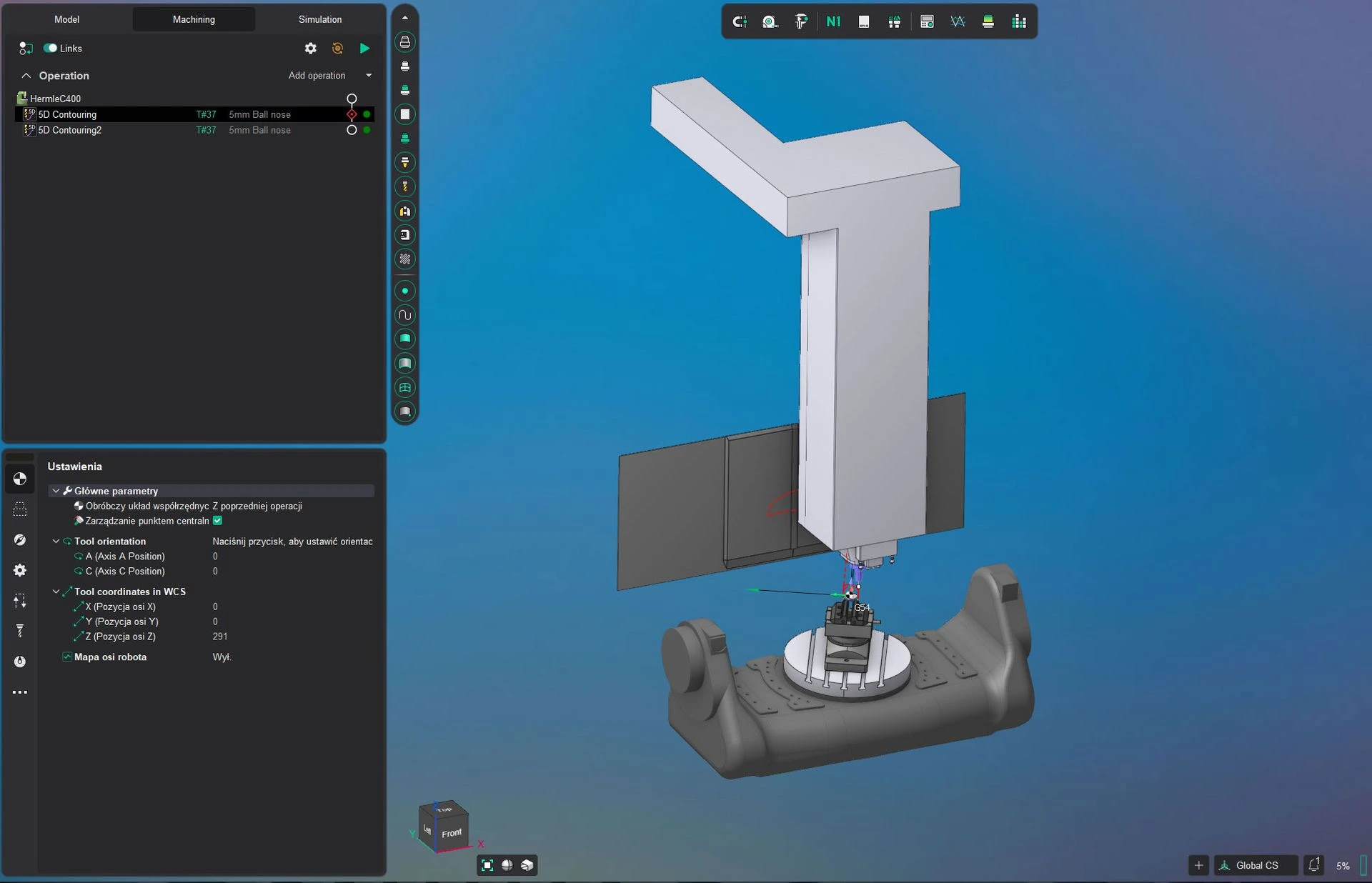

Maximum Precision

Execution of even the most demanding components.

Biocompatible Materials

We use materials suitable for medical applications.

Technical Support

Comprehensive technical consulting at every stage of the project.

Repeatability and Reliability

Quality assurance for both series and single-unit production.

Complete Confidentiality

We ensure the protection of technical documentation and project data.

What materials do you use in the production of medical components?

We most commonly use surgical-grade stainless steel, titanium, and specialized plastics approved for contact with the human body, including plastics resistant not only to a wide range of cleaning and disinfecting agents but also to various solvents. Additionally, medical-grade plastics can undergo steam sterilization using methods standard in the medical industry.

Do you manufacture single units or series?

We manufacture both single units as well as small and medium production series.

What is the lead time for manufacturing medical components?

The typical lead time depends on the complexity of the project, materials used, and quality requirements, and ranges from a few to several working days.

Need precision medical components? Contact us – we’ll find the best technological solutions for your project.