-

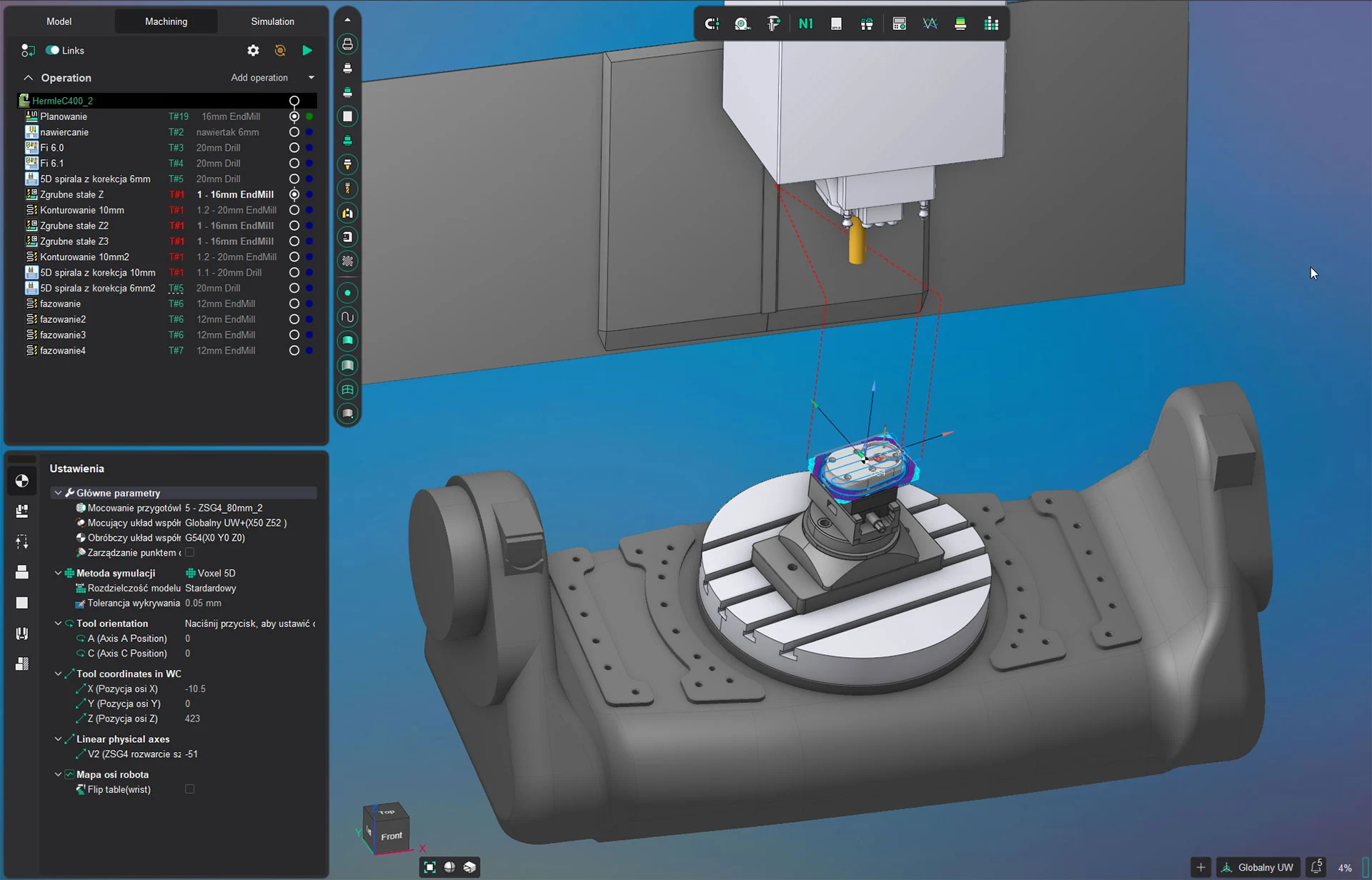

Najwyższa dokładność ±2 µm

Precyzja wymiarowa na najwyższym poziomie.

Własna hartownia

Kompleksowe procesy cieplno-chemiczne na miejscu.

Klimatyzowana hala produkcyjna

Stabilne warunki środowiskowe dla optymalnej precyzji.

Laboratorium pomiarowe

Szczegółowa kontrola jakości detali.

Ponad 50 specjalistów

Doświadczony zespół zapewniający kompleksową obsługę.

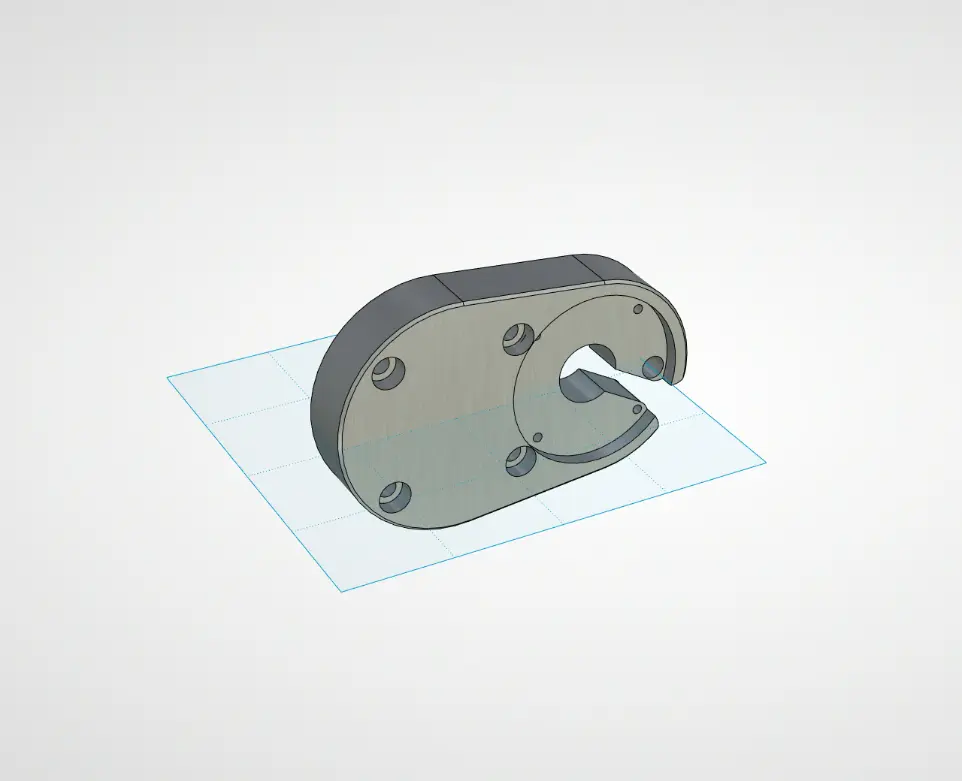

Zróżnicowany park maszynowy

Frezarki, tokarki, szlifierki oraz maszyny EDM.

Pełna poufność

Gwarancja bezpieczeństwa dokumentacji technicznej klientów.

Z jakich materiałów możecie wykonać elementy precyzyjne?

Najczęściej stosujemy stal nierdzewną, aluminium, mosiądz, tworzywa sztuczne, kompozyty, a także stal proszkową i narzędziową. Możemy również dostosować materiały do indywidualnych wymagań projektu.

Czy produkujecie pojedyncze detale czy serie?

Realizujemy zarówno pojedyncze detale, jak i produkcję seryjną.

Jaki jest czas realizacji elementów precyzyjnych?

Czas wykonania zależy od stopnia skomplikowania detali oraz ilości zamówionych elementów. Zazwyczaj realizacja zajmuje od kilku dni do kilkunastu dni roboczych.

Potrzebujesz elementów precyzyjnych? Skontaktuj się z nami – pomożemy Ci wybrać najlepsze rozwiązanie technologiczne dopasowane do Twojego projektu.