Czym jest kontrola jakości i dlaczego jest kluczowa?

Kontrola jakości to systematyczny proces monitorowania i oceny każdego etapu produkcji, który gwarantuje, że każdy wyrobiony element spełnia ściśle określone normy techniczne. Dzięki temu minimalizujemy ryzyko błędów, redukujemy koszty poprawek i budujemy zaufanie klientów.

Jakie metody kontroli jakości stosujemy?

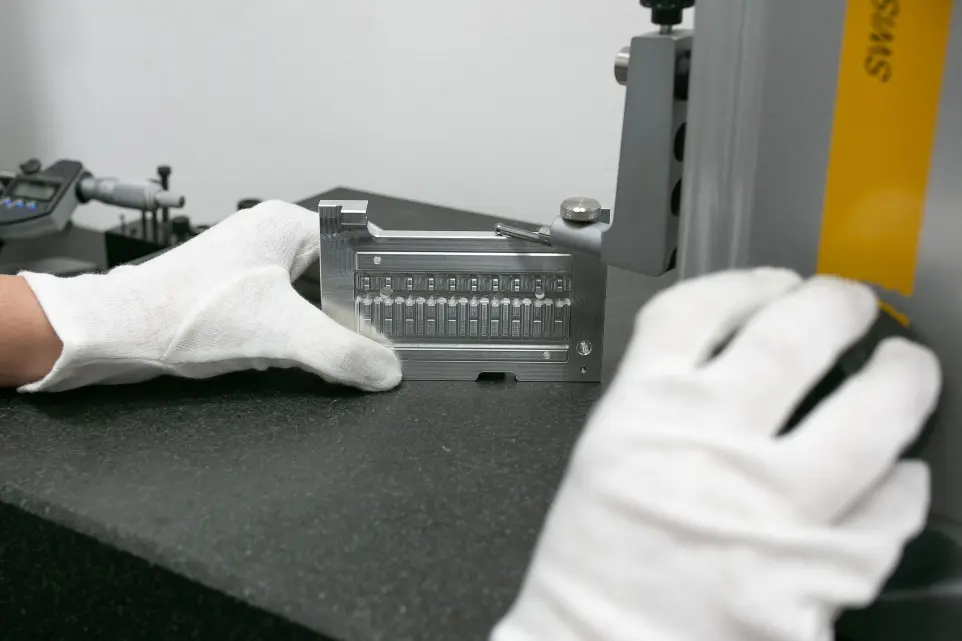

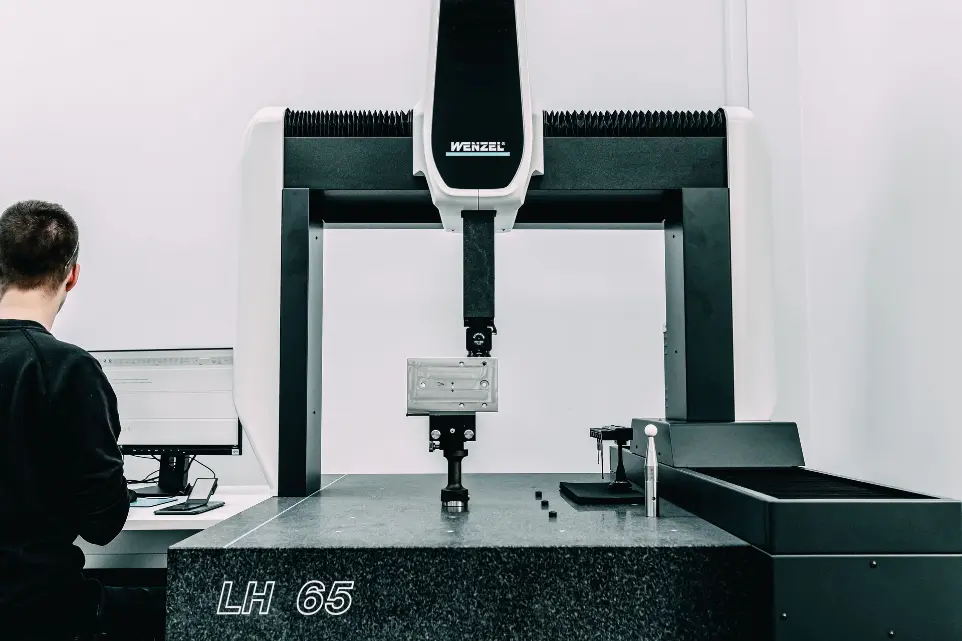

W firmie Sacher wykorzystujemy szereg zaawansowanych metod pomiarowych. Wśród nich znajdują się między innymi: maszyny CMM do wielowymiarowych pomiarów, mikroskopy pomiarowe, suwmiarki, mikrometry oraz wysokościomierze. Uzupełnieniem są profilometry, twardościomierze i płytki wzorcowe, które służą do kalibracji oraz dokładnej weryfikacji właściwości materiałów.

Jakie przyrządy pomiarowe wykorzystujemy?

Nasz proces kontroli jakości opiera się na precyzyjnych narzędziach, takich jak:

Mikroskopy pomiarowe

Umożliwiają obserwację mikroskopijnych detali

Twardościomierze

Służą do oceny właściwości mechanicznych materiałów

Profilometry

Analizują powierzchnię wyrobów

Wysokościomierze, suwmiarki i mikrometry

Dokonują precyzyjnych pomiarów wymiarowych

Płytki wzorcowe

Zapewniają dokładną kalibrację urządzeń pomiarowych

Jakie certyfikaty potwierdzają nasze standardy jakości?

Firma Sacher posiada certyfikat ISO 9001, który potwierdza spełnianie rygorystycznych norm zarządzania jakością. Dodatkowo wyróżnienie Ecovadis świadczy o odpowiedzialnych praktykach biznesowych i dbałości o zrównoważony rozwój, co jest integralną częścią naszych procedur kontroli jakości.

W jaki sposób narzędzia pomiarowe wpływają na efektywność produkcji?

Wykorzystanie precyzyjnych przyrządów, takich jak maszyny CMM, mikroskopy pomiarowe, profilometry, suwmiarki, mikrometry, twardościomierze, wysokościomierze oraz płytki wzorcowe, umożliwia nam wczesne wykrywanie ewentualnych niezgodności. To pozwala na szybkie wprowadzenie korekt, optymalizację procesów produkcyjnych oraz zapewnienie niezawodności i powtarzalności finalnych produktów.