-

Wsparcie techniczne

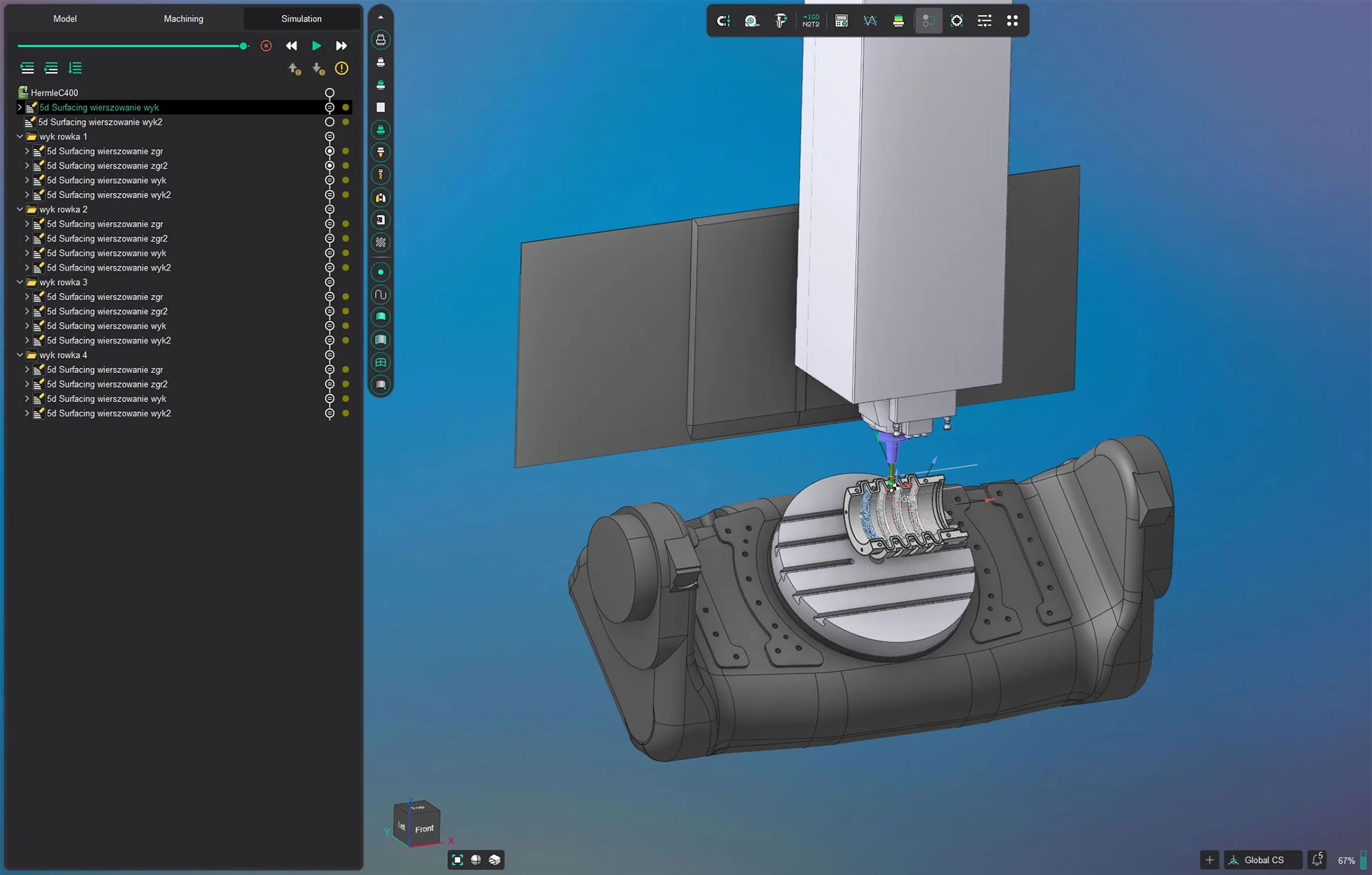

Pomagamy przy projektowaniu oraz doborze optymalnych technologii i materiałów.

Własna hartownia

Posiadamy własne zaplecze do hartowania narzędzi.

Szybka realizacja

Efektywnie realizujemy nawet najbardziej złożone projekty.

Pełna poufność

Zapewniamy bezpieczeństwo Twojej dokumentacji technicznej.

Precyzyjne wykonanie

Zgodność z dokumentacją techniczną i wysokie wymagania jakościowe.

Trwałość i odporność

Używamy materiałów o wysokiej wytrzymałości i twardości

Jakie dane są potrzebne do wykonania matrycy lub tłocznika?

Najlepiej dostarczyć dokumentację techniczną (rysunki 2D lub modele 3D). Możemy również wesprzeć Cię w opracowaniu dokumentacji od podstaw.

Czy produkujecie pojedyncze sztuki czy również serie?

Realizujemy zarówno pojedyncze egzemplarze, jak i serie produkcyjne.

Z jakich materiałów wykonujecie matryce i tłoczniki?

Najczęściej korzystamy z wysokogatunkowej stali narzędziowej, stali hartowanej, a także specjalistycznych stopów metali dostosowanych do specyficznych zastosowań.

Czy oferujecie powłoki PVD?

Tak, we współpracy z naszymi sprawdzonymi dostawcami oferujemy wszystkie rodzaje powłok PVD dostosowanych do potrzeb klienta.

Jaki jest czas realizacji zamówienia?

Czas wykonania zależy od złożoności projektu oraz rodzaju materiału. Zazwyczaj realizacja trwa od kilku do kilkunastu dni roboczych.

Chcesz zamówić matrycę lub tłocznik? Skontaktuj się z nami – pomożemy Ci dobrać optymalne rozwiązanie technologiczne.